Autumn is coming, give you 9 forklift maintenance advices

Summer has passed, the temperature began to cool after the fall, the climate changed significantly. The transition from summer to autumn, the forklift in the use of the process should pay special attention to maintenance. gzsycc.com suggest you, this season forklift maintenance should do the following: 1.A vehicle external forklift maintenance Autumn morning and evening dew more water, forklift surface is often very wet, if the body has obvious scratches, should be done in time to do paint treatment, so as not to scratches the site of moisture and corrosion. Due to the corrosion of rain acid and summer light point-blank, the forklift body paint will inevitably be oxidized, at the time of the season, you'd better do for the forklift from the surface cleaning, paint maintenance work. 2.Forklift Tire maintenance In the safe driving of the forklift, the tires play an important role. In the summer, due to the high temperature, forklift user always check the tire pressure, must not make the tire pressure is too high, otherwise, there will be the risk of forklift tire puncture. But to the fall, because the temperature is relatively low, the tire will add air pressure to make it Keep the specified pressure range, at the same time, should also check whether the tire scratches, because the rubber in the autumn and winter is easy to harden and more brittle, easy to leak the tires, and even tires, to regularly clean the inclusions within the tire. 3. Forklift maintenance of the engine compartment Should check the engine compartment of the engine oil, brake oil and antifreeze, to see if the oil is sufficient, whether the deterioration, whether to replace the cycle, the oil is like the vehicle's blood, to the replacement cycle must be replaced to ensure that the oil cycle unobstructed. 4. Forklift maintenance of barake system Autumn day and night temperature difference, easy to cause the forklift body parts expansion shrinkage deformation, you should always check whether the brake weak, deviation, brake pedal pedaling force has changed, if necessary, clean up the entire brake system piping part and pay attention to forklift maintenance. If your forklift is equipped with a warm air line or fan, after a summer operation, or for the upcoming cold winter to prepare, the fall of the most suitable for these devices to check whether the exhaust outlet is normal, the line is aging, etc. And so on, if any problem can be resolved in time. 5. Maintenance of air inlet or inlet grille To check whether these parts are debris, if there are debris, you can use compressed air blowing dust, in addition, forklift maintenance to the engine cooling state, you can use a water gun from the inside to wash the above parts. 6. Air conditioning maintenance If your forklift is equipped with air conditioning, hot summer weather, the car is often overloaded air conditioning operation, in addition, due to summer and autumn more rain, a long time, it is easy to rust the condenser...

Nissan TD27 H20-2 Clutch Drum 31511-51K00

Nissan TD27 H20-2 Clutch Drum 31511-51K00

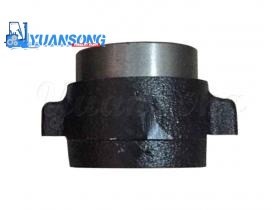

CT5400SA Bearing Clutch Release 3EB-10-31930 Komatsu C16 4D94LE

CT5400SA Bearing Clutch Release 3EB-10-31930 Komatsu C16 4D94LE

Toyota 5F 14Z 1FZ Piston Clutch Drum 32152-33900-71

Toyota 5F 14Z 1FZ Piston Clutch Drum 32152-33900-71

Komatsu FD30-12/14 Support Clutch Release Bearing 3EB-10-31120

Komatsu FD30-12/14 Support Clutch Release Bearing 3EB-10-31120

Toyota 8FD30 Wheel Brake 47040-26600-71/LH 47030-26600-71/RH

Toyota 8FD30 Wheel Brake 47040-26600-71/LH 47030-26600-71/RH

Komatsu FD25-16 Brake Drum 3EB-21-52320

Komatsu FD25-16 Brake Drum 3EB-21-52320

Toyota 5/6/7FD15 1DZ BRAKE DRUM 42431-13600-71

Toyota 5/6/7FD15 1DZ BRAKE DRUM 42431-13600-71

Toyota Brake Master Cylinder 47210-23321-71 Aisin BMW-001

Toyota Brake Master Cylinder 47210-23321-71 Aisin BMW-001