Insufficient output power during use of the forklift, difficulty in starting, slow response to shift,oil temperature is too high and torque converter does not work etc.this is usually a common failt in a forklift hydraulic mechanical transmission system.What should we do when these failures occur?

Failure analysis

During use, if the forklift is found to be underpowered, climbing is difficult, and shifting is unresponsive,While the lifting and lifting work normally, the pressure of the system can be used to detect the pressure of the system first,if it fails to reach the specified pressure value,the reasons is the compensation pump gear and pump body wear excessively,causes the increase of the internal leakage of the compensation pump; the poor cleanliness of the oil leads to the blockage of the oil circuit and compensates the suction.

If the oil temperature is too high,the reason is Insufficient oil supply from compensating pump due to blocked oil line,Cause the clutch to dry cause by excessive oil temperature;the oil pressure in the torque converter is lower than the adjustment pressure of the main pressure valve,cause the torque converter outlet pressure too low; the oil grade is wrong;torque converter internal components are damaged,so that only a small part of the power of the engine is transmitted to the turbine,excessive reactive power causes a sharp rise in oil temperature.

Troubleshooting

From the above analysis, we can see that the faults of the forklift hydraulic machinery transmission system are mainly the three links of the oil circuit, the torque converter and the compensation pump.Therefore, when troubleshooting,first consider cleaning the oil circuit,replace the oil and oil filter as required; then check the torque converter and the compensation pump three links.Therefore,when troubleshooting,first consider cleaning the oil circuit,replace oil and oil filter as required;then check the torque converter guide wheel,guide wheel seat and overrunning clutch for damage;finally check the compensating pump for wear and repair or replace damaged components.The dust and dirt on the surface of the oil radiator must also be cleaned.After the above processing,can usually better troubleshooting.

When inspecting machinery transmission system,attention should be paid to the following inspections;the concentricity error of the engine flywheel, torque converter and shell of the variable torque should not exceed 0.2mm;the degree of unbalance of the connecting plate should be less than 30g·cm;the end of the face of the engine flywheel housing and the end face of the converter housing relative to its axis shall not fluctuate more than 50um; there shall be 1.0-1.5mm clearance between the torque converter fork and the end face of the compensating pump gear.

The above are just some troubleshooting measures taken for some common faults that occur in the forklift hydraulic machinery transmission system.According to the actual situation for reference. Thank you!

Nissan TD27 H20-2 Clutch Drum 31511-51K00

Nissan TD27 H20-2 Clutch Drum 31511-51K00

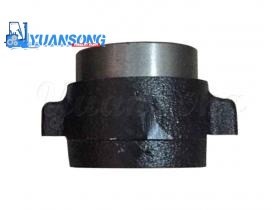

CT5400SA Bearing Clutch Release 3EB-10-31930 Komatsu C16 4D94LE

CT5400SA Bearing Clutch Release 3EB-10-31930 Komatsu C16 4D94LE

Toyota 5F 14Z 1FZ Piston Clutch Drum 32152-33900-71

Toyota 5F 14Z 1FZ Piston Clutch Drum 32152-33900-71

Komatsu FD30-12/14 Support Clutch Release Bearing 3EB-10-31120

Komatsu FD30-12/14 Support Clutch Release Bearing 3EB-10-31120

Toyota 8FD30 Wheel Brake 47040-26600-71/LH 47030-26600-71/RH

Toyota 8FD30 Wheel Brake 47040-26600-71/LH 47030-26600-71/RH

Komatsu FD25-16 Brake Drum 3EB-21-52320

Komatsu FD25-16 Brake Drum 3EB-21-52320

Toyota 5/6/7FD15 1DZ BRAKE DRUM 42431-13600-71

Toyota 5/6/7FD15 1DZ BRAKE DRUM 42431-13600-71

Toyota Brake Master Cylinder 47210-23321-71 Aisin BMW-001

Toyota Brake Master Cylinder 47210-23321-71 Aisin BMW-001