Emergency repair forklift tips, forklift trucks out of shovel inevitably some failure, we must temporarily take some emergency repair methods. Now I introduce some easy-to-use garage tips to you at Gzsycc.com.

1、Forklift radiator damage. When the forklift is in use, it is found that the fuel radiator is leaking oil. The oil drain can be wiped clean and smeared with soap or bubble gum on the oil spill site for temporary plugging; repairing with epoxy adhesive is better.

2、Forklift oil hose rupture. When oil hose ruptured can be at ruptured cleaned, coated with soap, wrapped with tape or tape wrapped in the pipe rupture, and tied with wire, and then coated with a layer of soap.

3、Forklift tubing break. when tubing broken can find a diameter and adapt to the hose rubber or Plastic sleeve joint. If the socket is not tight enough, the two ends of the wire bundled to prevent leakage.

4、Forklift Cylinder Head ect parts appear trachoma and leakage, leakage. According to the size of trachoma, use the appropriate specifications of the electrician fuse, with a hammer gently smashed into the trachoma, you can eliminate oil spills, leaking.

5、Oil hose spill. When the forklift is used, such as the oil leakage of the oil pipe joint, the oil hose horn and the oil hose nut are mostly not sealed. Available cotton yarn wrapped around the lower edge of the horn, and then tighten the tubing nut and tubing joints; but also the bubble gum or malt sugar chewed into a paste, painted in the tubing nut seat, to be dry after the sealing effect. Can also be cut leather or leather belt shape or put into the hole smashing molding, can be installed,can also cut a piece of plastic pipe for installation.

6、Cups cracked. Use a tape tube or plastic tube to put the sediment cup in and out of the tubing sleeve so that the oil will not flow through the sedimentation cup.

7、In and out of the hose rupture. Rupture is not big, can be coated with a layer of soap coated cloth will be watertight Department dressing; rupture larger, you can cut off the hose rupture, in the middle of a bamboo or iron pipe, and used bundled with wire.

8、Fan belt broken. The broken belt can be tied with wire or a good way to open and stop the car drove away.

9、Screw hole slider. Screw hole slip caused oil leakage or connecting rod loose, so that it can not work. At this time, the original screw can be hammer-sharpened with a hammer so as to increase the expansion on both sides (pay attention to not buckling the hammer at the top to fasten the hole), and then fasten it well. but it can not be disassemnle repeatedly until maintenance next time.

10、Diaphragm or delivery pump diaphragm ruptures or breaks. Detachable oil pump to remove the diaphragm, with bakelite, electrical insulating bakelite or plastic sheeting prototype size saw file molding, and polished fitted; or the tubing directly to the injection pump.

11、Door spring broken.After the valve spring is broken, the broken spring can be taken off,and then you can install the broken two sections reverse.You can also find a 1 mm thick sheet of metal, cut into 1 mm larger than the diameter of the spring disc, cut a circular hole inside, the diameter is less than 4 mm in diameter, the outer edge cut every 6 mm cut 4 mm long cut, cut Good after every other one folded, forming a double-sided spring seat groove, and then turn the spring loaded into the metal tank can be used. If the spring is broken into several sections, the cylinder inlet and exhaust valve adjustment screw can be removed, so that the valve remains closed, so that the cylinder to stop working.

The above described some problems when the forklift emergency repair methods, according to the actual situation for reference. Thank you!

Nissan TD27 H20-2 Clutch Drum 31511-51K00

Nissan TD27 H20-2 Clutch Drum 31511-51K00

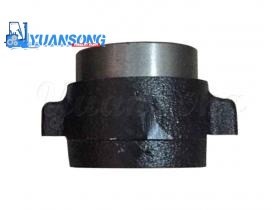

CT5400SA Bearing Clutch Release 3EB-10-31930 Komatsu C16 4D94LE

CT5400SA Bearing Clutch Release 3EB-10-31930 Komatsu C16 4D94LE

Toyota 5F 14Z 1FZ Piston Clutch Drum 32152-33900-71

Toyota 5F 14Z 1FZ Piston Clutch Drum 32152-33900-71

Komatsu FD30-12/14 Support Clutch Release Bearing 3EB-10-31120

Komatsu FD30-12/14 Support Clutch Release Bearing 3EB-10-31120

Toyota 8FD30 Wheel Brake 47040-26600-71/LH 47030-26600-71/RH

Toyota 8FD30 Wheel Brake 47040-26600-71/LH 47030-26600-71/RH

Komatsu FD25-16 Brake Drum 3EB-21-52320

Komatsu FD25-16 Brake Drum 3EB-21-52320

Toyota 5/6/7FD15 1DZ BRAKE DRUM 42431-13600-71

Toyota 5/6/7FD15 1DZ BRAKE DRUM 42431-13600-71

Toyota Brake Master Cylinder 47210-23321-71 Aisin BMW-001

Toyota Brake Master Cylinder 47210-23321-71 Aisin BMW-001