How to repair the forklift's drive axle?

When the forklift is unloading cargo or moving cargo,the drive axle is to bear most of the weight,If the road is uneven and the load of the forklift truck is not uniform,the drive axle will be bent,fractured,worn out of the axle shaft bearing bore,and worn by the axle shaft journal.Then when the drive axle has a low degree of damage,the following inspections and repairs can be made: 1.Forklift drive axle housing bending inspection and repair: 1) Drive axle housing bending test.Before the inspection,the flatness of the contact surfaces of the axles and brake drum ends should be corrected first,Eliminate the circular runout error of the end face and mount the standard half shaft on the drive axle housing,correct the bearing and test the center position of the left and right axles from the shell to judge whether there is any bending.The difference between the two axes should not exceed 0.75mm. 2) When the drive axle housing is bent beyond the limit, it should be corrected.When correcting, the correction deformation should not be greater than the original bending deformation,and maintain the calibration pressure for a period of time,make the axle shell plastic deformation.If the deformation is too large and the bending deformation is greater than 2mm, it can be corrected after preheating, but the heating temperature must not exceed 700°C. 2.Forklift drive axle housing fracture repair: when cracks and cracks appear in the middle of the drive axle housing,they can be repaired by welding.The operating points are as follows: 1) A v-shaped groove with a 90° angle along the crack has a depth of 2/3 of the thickness. 2) At a distance of 6-10 mm from both ends of the crack,drill holes of 5 mm in diameter. 3) Welding repair cracks,the solder layer should be higher than the base metal,but not more than 1mm.After welding on the front side,weld repairs are made on the opposite side,and the welding seam should be flattened after welding.If the weld is repaired at the work plane, the flatness error should not exceed 0.25mm. 4) After the crack repair welding,the reinforcing web should be welded at the crack,and its thickness is generally 4-6mm.The reinforced web should be symmetrical with the center of the drive axle housing. 5) If the crack penetrates to the drive axle housing cover or the final drive flange plane,the reinforcing ring should be welded after welding.The reinforced abdominal ring of the drive axle housing cover can be reused outside,the main reducer shell depends on the permit of the interior space,should be multiplexed on the inside.When reinforcing the abdominal ring by welding,tighten the reinforcing abdominal ring with a bolt and press it on the flat surface first to avoid position shifting and deflection during welding. 6) After welding repair strengthened drive axle housing,to recheck the straightness error,flatness error of shell cover and final drive flange plane,and corrected and ground to meet the standards. 3.Inspection and repair of othe...

Nissan TD27 H20-2 Clutch Drum 31511-51K00

Nissan TD27 H20-2 Clutch Drum 31511-51K00

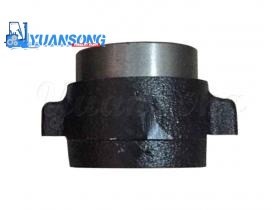

CT5400SA Bearing Clutch Release 3EB-10-31930 Komatsu C16 4D94LE

CT5400SA Bearing Clutch Release 3EB-10-31930 Komatsu C16 4D94LE

Toyota 5F 14Z 1FZ Piston Clutch Drum 32152-33900-71

Toyota 5F 14Z 1FZ Piston Clutch Drum 32152-33900-71

Komatsu FD30-12/14 Support Clutch Release Bearing 3EB-10-31120

Komatsu FD30-12/14 Support Clutch Release Bearing 3EB-10-31120

Toyota 8FD30 Wheel Brake 47040-26600-71/LH 47030-26600-71/RH

Toyota 8FD30 Wheel Brake 47040-26600-71/LH 47030-26600-71/RH

Komatsu FD25-16 Brake Drum 3EB-21-52320

Komatsu FD25-16 Brake Drum 3EB-21-52320

Toyota 5/6/7FD15 1DZ BRAKE DRUM 42431-13600-71

Toyota 5/6/7FD15 1DZ BRAKE DRUM 42431-13600-71

Toyota Brake Master Cylinder 47210-23321-71 Aisin BMW-001

Toyota Brake Master Cylinder 47210-23321-71 Aisin BMW-001