Internal-combustion forklift engine are forklifts powered by diesel engines using diesel, gasoline, or liquefied petroleum gas as fuel,power from the engine provided.Because of the different fuels used in the engine, the internal combustion forklift engine is divided into two categories: gasoline engine and diesel engine.Is there a difference between operational principle by the two?This article takes you to find out.

Type of the internal-combustion forklift engine

1.Gasoline engine is generally made by carburetor that to make gasoline and air after mixed into the cylinder, and then use spark to ignite bursts of work, so it is called carburetor engine.

2.The diesel engine generally injects diesel into the cylinder through the fuel injection pump and an injector, and mixes with the high-temperature and high-pressure air that has already been sucked into the cylinder (and is compressed), cause spontaneous combustion and work.Therefore, the diesel engine is also called a compression ignition engine.

The structure of the gasoline engine:(Note:The composition of the diesel engine is almost the same as that of the gasoline engine, except that there is no ignition system, and a high-pressure injection pump is added to the fuel supply system. So split the gasoline engine.)

1.Body: It is the assembly matrix of engine parts.It includes a cylinder head, a cylinder block, and a lower crankcase (oil sump).The combusiton chamber parts of it is the inner wall of the cylinder block cylinder head and cylinder block constituent.Many parts of the body are also part of other systems constituent.

2.Crank Mechanism:It is a mechanism by which the engine generates and transmits power. It converts linear reciprocating motion of the piston into rotational motion of the crankshaft and outputs power.It includes pistons, piston pins, connecting rods, crankshafts with flywheels, and cylinder blocks etc.

3.Gas distribution mechanism:Including intake valve, exhaust valve, valve lifter and camshaft and camshaft timing gear (driven by the crankshaft timing gear) and so on.Its role is to make the combustible mixture full of cylinders in time and discharge the exhaust gas from the cylinder in time.

4.Fuel Supply System:The gasoline engine fuel supply system includes a gasoline tank, a gasoline pump, a gasoline filter, an air filter, a carburetor, an intake pipe, an exhaust pipe, an exhaust muffler etc.Its role is to mix the gasoline and air into a suitable combustible gas mixture for supply to the cylinder for combustion and to discharge the combustion-generated exhaust gas to the engine.

5.cooling system:It mainly includes water pumps, radiators, fan fans, water distribution pipes and cylinder blocks, and water jackets in cylinder heads.Its function is to dissipate the heat of the high heat components into the atmosphere to ensure the normal operation of the engine.

6.Lubrication system:Including oil pumps, pressure limiting valves, oil channels, filters, oil filters, and oil radiators.Its role is to supply lubricating oil to the friction parts to reduce the frictional resistance between them, reduce the wear of the parts, and partially cool the friction parts and clean the friction surface.

7.

Starting system:Including the engine starting mechanism and its accessories.

We have models of various types for your choice at

gzsycc.com, if you need to contact our company, thank you!

Nissan TD27 H20-2 Clutch Drum 31511-51K00

Nissan TD27 H20-2 Clutch Drum 31511-51K00

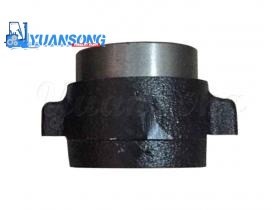

CT5400SA Bearing Clutch Release 3EB-10-31930 Komatsu C16 4D94LE

CT5400SA Bearing Clutch Release 3EB-10-31930 Komatsu C16 4D94LE

Toyota 5F 14Z 1FZ Piston Clutch Drum 32152-33900-71

Toyota 5F 14Z 1FZ Piston Clutch Drum 32152-33900-71

Komatsu FD30-12/14 Support Clutch Release Bearing 3EB-10-31120

Komatsu FD30-12/14 Support Clutch Release Bearing 3EB-10-31120

Toyota 8FD30 Wheel Brake 47040-26600-71/LH 47030-26600-71/RH

Toyota 8FD30 Wheel Brake 47040-26600-71/LH 47030-26600-71/RH

Komatsu FD25-16 Brake Drum 3EB-21-52320

Komatsu FD25-16 Brake Drum 3EB-21-52320

Toyota 5/6/7FD15 1DZ BRAKE DRUM 42431-13600-71

Toyota 5/6/7FD15 1DZ BRAKE DRUM 42431-13600-71

Toyota Brake Master Cylinder 47210-23321-71 Aisin BMW-001

Toyota Brake Master Cylinder 47210-23321-71 Aisin BMW-001