——Can't the forklift diesel engine start?

An article teaches you how to troubleshoot the causes of diesel engine failures yourself!

After purchasing a forklift, I had to rent a forklift because of a breakdown of the forklift.

It was obviously not a big problem, but because I didn't understand the forklift, I had to wait for the maintenance staff to come and inspect it.

Obviously there is no need to replace the parts, but because I don't understand it, I spent a lot of money in the repair shop.

......

Are you also troubled by these problems? In order to solve these problems, Guangzhou Yuansong Forklift Parts Trading Co., Ltd. will publish an article once a month from June on how to find the causes of the failure of each part of the forklift. Each forklift user can check and repair his forklift by himself, so that customers can save costs and time.

Failure analysis of diesel engine not starting

1. Low startup speed

Reason 1: The battery is insufficient or the wiring is loose

Troubleshooting method: try again after fully charged; tighten the wiring; check the terminal.

Reason 2: Motor failure of the starter

Troubleshooting method: there are too many reasons, please refer to the starter motor faults for details

2. The fuel system is abnormal

Reason 1: There is no oil in the fuel tank or the valve of the fuel tank is not open

Troubleshooting method: check the fuel tank and fill it up; check whether the fuel tank valve is open

Reason 2: There is air in the fuel system; water in the oil; oil leakage at the joint

Troubleshooting method: remove air; replace diesel; tighten joints

Reason 3: The oil circuit is blocked

Troubleshooting method: clean the pipeline, replace the filter element of the diesel filter, clean the oil inlet pipe of the oil transfer pump

Reason 4: The oil pump does not supply oil

Troubleshooting method: check whether the oil transfer pump inlet pipe is leaking, and check whether the oil transfer pump is faulty

Reason 5: Injector does not inject fuel or injects less fuel, and the pressure is too small, resulting in poor atomization; the pressure regulating spring of the fuel injector is broken; the nozzle hole is blocked

Troubleshooting method: disassemble and repair the injector and adjust it on the injector test bench

Reason 6: The fuel injection pump outlet valve leaks, the spring is broken; the plunger and the parts are worn

Troubleshooting method: repair or replace parts

3. Insufficient compression pressure

Reason 1: The valve clearance is too small

Troubleshooting method: resize according to the provisions

Reason 2: Valve leak

Troubleshooting method: grinding valve

Reason 3: Air leakage at the cylinder head gasket

Troubleshooting method: replace the cylinder head gasket and tighten the cylinder head bolts as required

Reason 4: piston ring wear, bonding, overlapping open position

Troubleshooting method: replace or clean and adjust the piston ring

4. The oil has no pressure or the pressure is too low

Reason 1: Too little engine oil or the engine oil deteriorates and becomes thinner

Troubleshooting method: add oil or change oil

Reason 2: The oil pipe is ruptured, and the oil pipe joints are not tightly compressed, resulting in oil leakage; the oil pressure gauge is damaged

Troubleshooting method: welding or replacing the oil pipe; tightening the oil pipe joint; replacing the oil pressure gauge

Reason 3: The end face clearance of the oil pump rotor is too large

Troubleshooting method: repair or replace directly

Reason 4: The matching clearance of each bearing is too large

Troubleshooting method: repair or replace directly

Reason 5: The oil passage bolt is loose or leaking

Troubleshooting method: check the oil passage bolts and plug the leaking position

5. The oil pressure is too high

Reason 1: The oil pump pressure limiting valve is not working properly, and the oil return is not smooth

Troubleshooting method: check and adjust it

Reason 2: The temperature is too low, resulting in high oil viscosity

Troubleshooting method: use the specified engine oil and cool down after the forklift is heated

6. There is no oil on the rocker shaft

Reason 1: Engine oil is on the cylinder head oil passage and rocker shaft support

Troubleshooting method: cleaning or dredging

7. The exhaust emits black smoke

Reason 1: The injector is blocked by carbon deposits and the needle valve is stuck

Troubleshooting method: check, repair or replace

Reason 2: overloading

Troubleshooting method: adjust the load and use it within the specified range

Reason 3: The fuel injection is too late, and part of the fuel burns during the exhaust process

Troubleshooting method: adjust the fuel supply pump

Reason 4: Incorrect valve clearance and poor valve sealing

Troubleshooting method: check valve clearance, valve sealing surface contact, valve spring force, etc. and remove defects

Reason 5: The fuel supply of each cylinder of the fuel injection pump is uneven

Troubleshooting method: adjust the oil supply of each cylinder

Reason 6: The intake pipe and air filter are blocked, and the air intake is not smooth

Troubleshooting method: clean the air filter

Reason 7: oil discharge pressure is too low, poor atomization, oil dripping

Troubleshooting method: check, adjust, repair or replace the nozzle assembly

Reason 8: The cooling water temperature is too low

Troubleshooting method: increase the cooling water temperature

Reason 9: Water in the combustion chamber

Troubleshooting method: check the cylinder head gasket

8. Blue smoke from exhaust

Reason 1: Excessive wear of the piston ring, or insufficient elasticity due to carbon deposits, and engine oil fleeing into the combustion chamber

Troubleshooting method: clean or replace the piston ring

9. Other reasons

Reason 1: The temperature is too low, resulting in high oil viscosity

Troubleshooting method: pour hot water into the cooling system and use the specified brand of engine oil

Reason 2: There is water in the combustion chamber or cylinder liner

Troubleshooting method: check, repair, replace

Nissan TD27 H20-2 Clutch Drum 31511-51K00

Nissan TD27 H20-2 Clutch Drum 31511-51K00

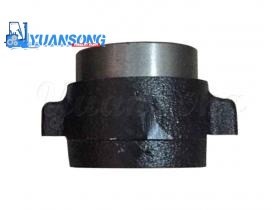

CT5400SA Bearing Clutch Release 3EB-10-31930 Komatsu C16 4D94LE

CT5400SA Bearing Clutch Release 3EB-10-31930 Komatsu C16 4D94LE

Toyota 5F 14Z 1FZ Piston Clutch Drum 32152-33900-71

Toyota 5F 14Z 1FZ Piston Clutch Drum 32152-33900-71

Komatsu FD30-12/14 Support Clutch Release Bearing 3EB-10-31120

Komatsu FD30-12/14 Support Clutch Release Bearing 3EB-10-31120

Toyota 8FD30 Wheel Brake 47040-26600-71/LH 47030-26600-71/RH

Toyota 8FD30 Wheel Brake 47040-26600-71/LH 47030-26600-71/RH

Komatsu FD25-16 Brake Drum 3EB-21-52320

Komatsu FD25-16 Brake Drum 3EB-21-52320

Toyota 5/6/7FD15 1DZ BRAKE DRUM 42431-13600-71

Toyota 5/6/7FD15 1DZ BRAKE DRUM 42431-13600-71

Toyota Brake Master Cylinder 47210-23321-71 Aisin BMW-001

Toyota Brake Master Cylinder 47210-23321-71 Aisin BMW-001